Your source of solutions for industrial applications

The advance of digitalisation has had a significant impact on the industrial environment, from smart manufacturing to smart mobility, smart infrastructure to smart homes and smart buildings. The introduction of 5G combined with innovations in sensor technology mean that decentralised systems and real-time availability in industrial production are now a reality.

At the same time, the need for communication, bandwidth and reliability is enormous and continuing to grow. With the emergence of the Industrial Internet of Things and demands for more sustainability and greater efficiency, automated machines and components, networked devices and infrastructure, and sustainable energy production and consumption have become a reality in recent years. These developments have only been possible due to industry, which provides the infrastructure for such applications to function properly and securely.

The next industrial revolution

The sheer variety of industrial applications – from advanced robotics, smart grids and connected infrastructure to innovative charging infrastructure and predictive maintenance – means that there is also a vast range of technological requirements. In order to meet these requirements as effectively as possible, AT&S offers maximum flexibility and the ability to adapt quickly to changing specifications and technologies in the development and production of innovative printed circuit board solutions.

AT&S combines a global presence with local support all around the world, making it a key partner for any industrial application.

AT&S’s key technologies for industrial applications made the following possible:

We give customers what they need

Whether you need power devices, machine-to-X modules, machine vision sensors or mmWave applications, AT&S can provide the perfect PCB and interconnect solution from small series production to mass production, and enables customers all over the world to set new standards with their many applications.

AT&S’ portfolio encompasses key technologies for all areas of industrial applications:

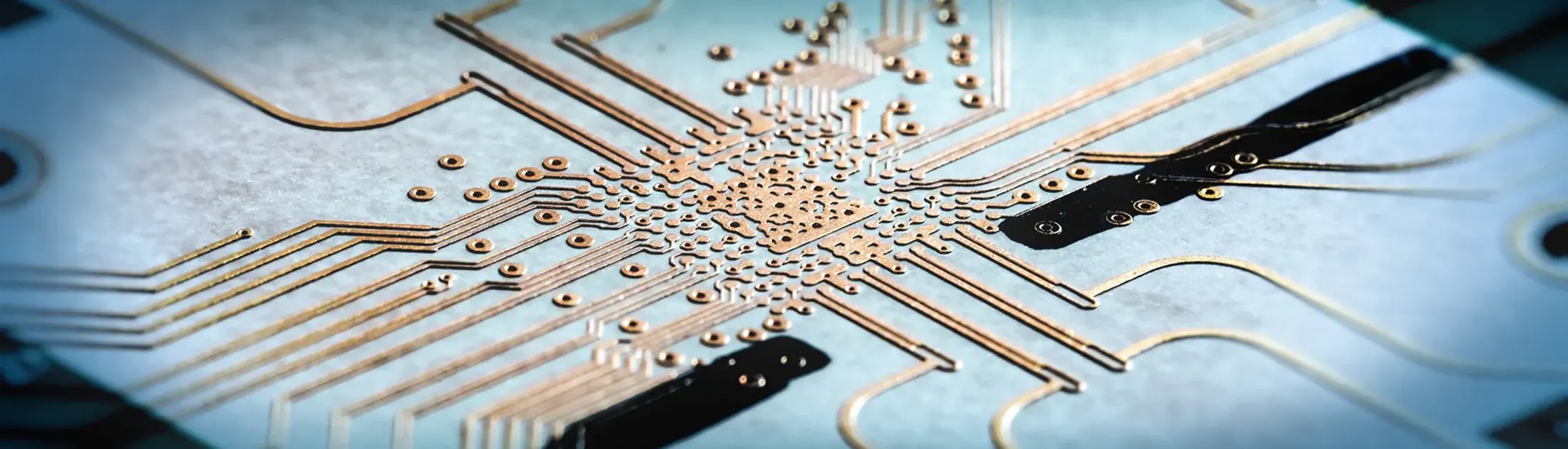

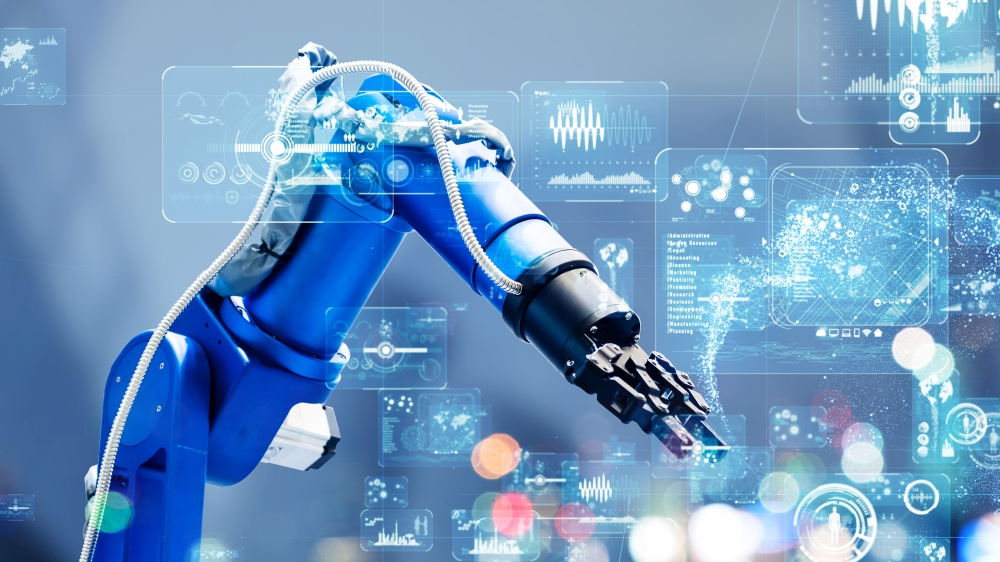

Flexible and smart: Industrial robots are revolutionising production

In the early 20th century, Henry Ford revolutionised car manufacturing by introducing assembly line production in his factories. In doing so, he changed the world: the automobile became an affordable mass product that transformed our idea of mobility and distance. The first industrial robot was developed half a century later, weighed around a tonne and had the form that we would recognise today: a metal arm with several joints guaranteeing freedom of movement around three axes. Yet, while robots have facilitated the production of cars, metal parts and machines, they have not had the same impact as the introduction of the assembly line.

You may also be interested in these topics

Since the beginning of time, man has produced a product with outstanding reliability: waste. However, what has rotted for thousands of years has grown over our heads since industrialization and consumer society thanks to non-rotting waste.

Industrial robots are getting smarter and smarter - soon it will be possible that humans will work hand-in-hand with their mechanical counterparts.

The mSAP technology enables the development of a new geometry for printed circuit boards which provides for faster data connections – an extremely important feature in the information society.