Double-sided printed circuit boards

The foundation of the electronics industry

Double-sided plated-through printed circuit boards of the kind long found in standard TV remote controls are the basis of the modern electronics industry. They opened the way for increasingly complex printed circuit board designs and are still used today as a cost-effective, comparatively easy-to-manufacture basis for many electronic systems and circuits.

Product benefits at a glance

- The simple structure allows for better heat dissipation.

- Metal cores or copper inlays can enhance heat dissipation for applications subject to high thermal stress.

- Double-sided printed circuit boards are a cost-effective option for installing electronic circuits.

Magnetic inlays for wireless charging

AT&S is participating in an EU research project to develop the next generation of miniaturised inductors for integration into printed circuit boards. This will make it open the way for tiny voltage converters and ultra-thin wireless charging devices that have enormous advantages over the technology currently available.

Heat resistant

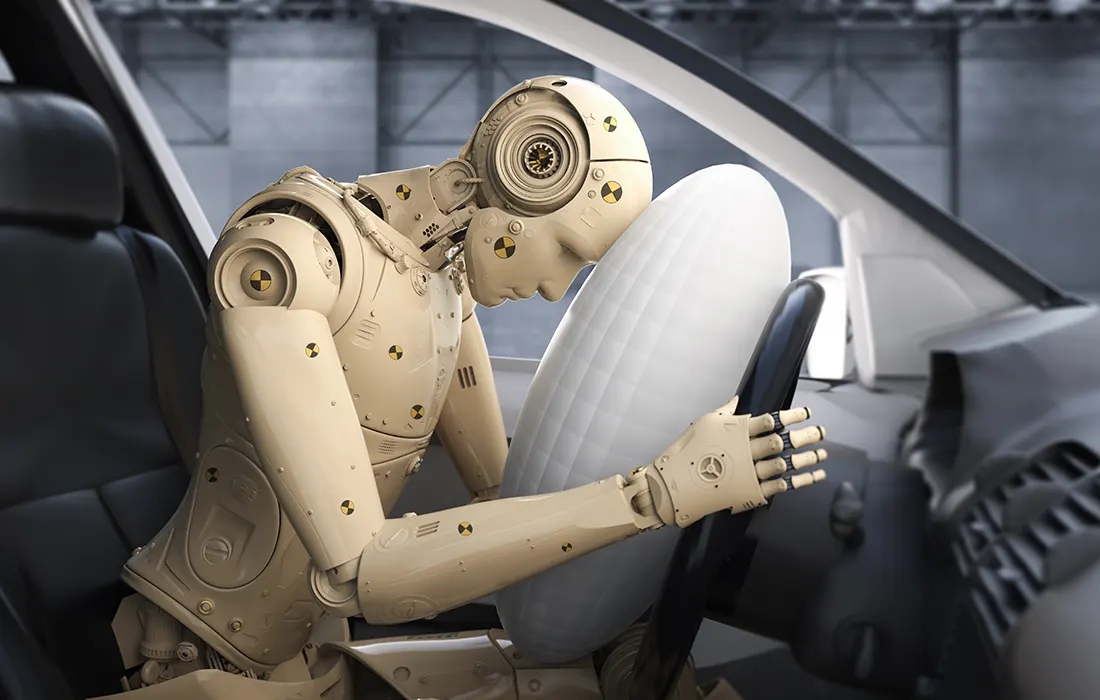

These double-sided printed circuit boards are now produced in thicknesses from 0.1 to 3.2 millimetres. If necessary, they can also be fitted with a metal core for higher thermal conductivity and copper inlays to manage waste heat. Double-sided printed circuit boards are used in electrical switches, air conditioning systems, ABS systems, airbags and taillights, for example.

Double-sided printed circuit boards with a metal core of copper or aluminum are mainly found in LED lamps for lighting systems. A rather more complex version with small copper discs as inlays is used in the automotive industry so that control systems components that generate a lot of heat can be used directly on the circuit board.

Due to their superb heat dissipation properties, our double-sided circuit boards are ideal for applications involving high currents.

Devices with comparatively simple circuits, such as air conditioning units, use double-sided printed circuit boards.

When combined with metal elements, double-sided printed circuit boards can also be used for applications involving the generation of high temperatures.

Double-sided PCBs are a mature technology that performs its tasks reliably and cost-effectively.

The workhorse of the electronics industry

Double-sided printed circuit boards are the foundation of microelectronics. Their tried-and-tested technology and low cost continue to make them attractive to customers

Double-sided printed circuit boards have also proved to be a cost-effective option for implementing electronic systems in medical technology and industrial projects, because they are relatively easy to produce by the standards of technology today. They will continue to be indispensable for many tasks in the electronics industry. Thanks to mature process technologies, they offer a wide range of options for system manufacturers at low production costs.

You may also be interested in these topics

As part of the "IPCEI on Microelectronics and Communication Technologies" funding project, the European Union is supporting research institutions and industrial partners in the development of technology that will enable a sustainable yet powerful data infrastructure for the continent. AT&S is involved in the project as a manufacturer of highly efficient substrates for the next generation of microchips. New research and production capacities in Leoben will play a decisive role in the modernization of the European microelectronics industry.

From ChatGPT to EU regulation of artificial intelligence: 2023 has ushered in a new phase of digitalization that will transform our society.