BT PCBs for Medical Devices

BT PCBs for Medical Devices

Medical devices, once stationary and large, are nowadays becoming smaller, smarter and ever more wearable. Each advancement in medical technology brings with it the expectation for devices that are not only completely reliable but also enhanced with new features.

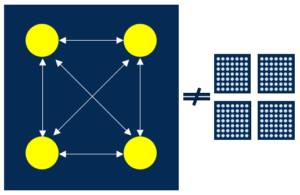

To accommodate artificial intelligence (AI) applications, rechargeability options, connectivity to multiple devices, and miniaturized designs, medical devices require more than traditional solutions. BT PCBs are the next generation of PCBs, which enable innovation for medical devices.

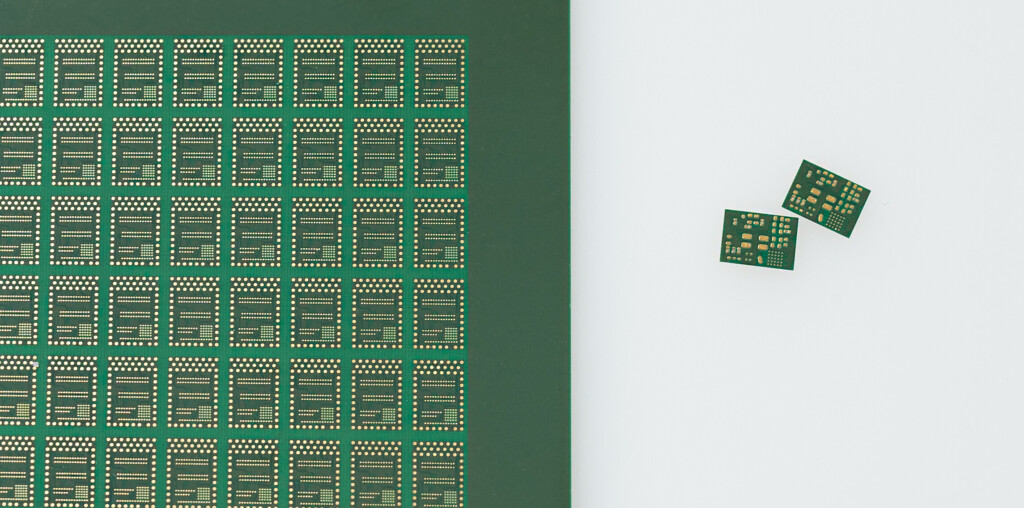

BT PCBs are high-density interconnect (HDI) PCBs that are built using Bismaleimide Triazine (BT) resin base materials. BT materials are widely used in IC substrate production as a cost-effective alternative to ceramics and other substrates.[1]

BT PCBs provide the basis for advanced electronic platforms that enable medical devices stay ahead of the curve technologically. BT PCBs enable miniaturized designs, allowing designers to select the most advanced components to integrate different functionalities into medical devices while fulfilling the rigorous reliability requirements.

[1] (Mitsubishi Gas Chemical, 2024)

| Parameter | Standard FR4 | Polyimide (PI) |

|---|---|---|

| CTExy | 14-19 ppm/K | 22-25 ppm/K |

| CTEz | 38-47 ppm/K | 22-25 ppm/K |

Table 1: Comparison of CTE values between FR4 and PI.

Limitations of standard PCBs

Standard PCBs have a number of limitations that hinder innovative designs. Some of the limitations discussed here are related to dimensional stability and miniaturization.

When referring to dimensional stability, one key parameter that indicates the level of stability on a PCB is the coefficient of thermal expansion (CTE). Looking at the CTE on XY-axis and Z-axis, the average values for standard FR4 material are in the range of: 14-19 ppm/K on XY-axis and 38-47 ppm/K in Z-direction. If we look at Polyimide (PI) materials used in traditional flexible PCB production, the CTE values are in the range of: 22-25 ppm/K on XY-axis and in Z-direction.

This single characteristic of standard PCB materials, be it FR4 or PI, results in a number of limitations for advanced designs. Some of these limitations are:

- Higher CTE in XY direction leads to higher tolerance required for assembly.

- Higher CTE in XY direction results in limited annular rings, and photo & soldermask registration capabilities during PCB production.

- Higher CTE in XY direction might introduce stress into the electronic package due to the CTE mismatch between the PCB and the components used.

- Higher CTE in Z direction leads to higher total thickness tolerance of the finished PCB.

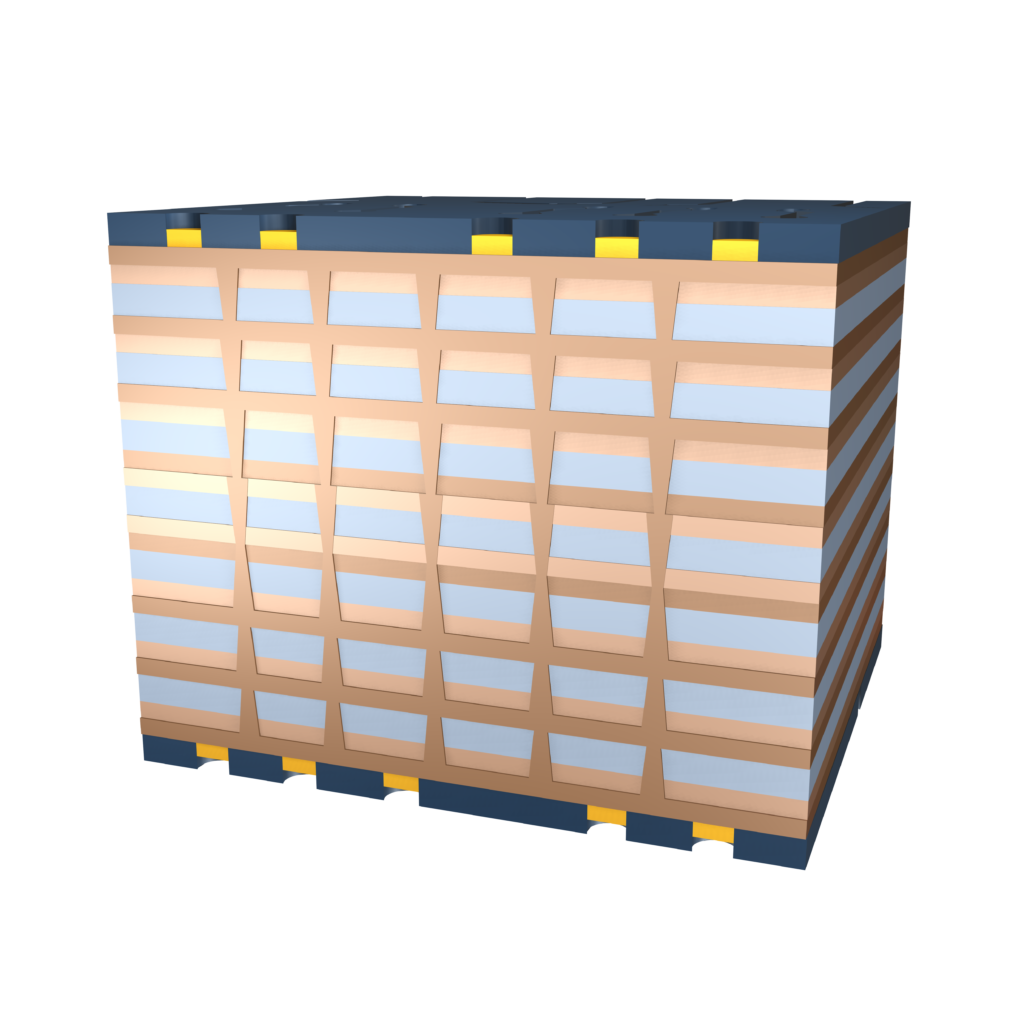

- Higher CTE in XY and Z axes introduces interconnection weaknesses into stacked anylayer PCB designs with multiple press cycles.

Only looking at dimensional stability as seen under one parameter (CTE), highlights some of the limitations of traditional PCBs. Miniaturization possibilities are consequently dictated by the choice of PCB and PCB materials.

Advantages of BT PCBs

BT PCBs are PCBs built using BT materials. BT materials are composed of BT resin and glass fibers. The resin adds some extraordinary properties to the base material such as high thermal and dimensional stability and excellent electrical properties.

| Parameter | Standard FR4 | Polyimide (PI) | BT Material |

|---|---|---|---|

| CTExy | 14-19 ppm/K | 22-25 ppm/K | 6-8 ppm/K |

| CTEz | 38-47 ppm/K | 22-25 ppm/K | 22-26 ppm/K |

Table 2: Comparison of CTE values between FR4, PI and BT.

Focusing on dimensional stability and miniaturization, the advantages of BT PCBs over traditional FR4 or flexible PCBs becomes evident. The CTE values for BT material are in the range of: 6-8 ppm/K in XY-direction and 22-26 ppm/K in Z-direction. In comparison to traditional PCBs using FR4 materials, BT PCBs have CTE values two-times lower in the XY & Z directions. Compared to flexible PCBs, BT PCBs have CTE values three-times lower in XY-directions.

Due to their low CTE, BT PCBs offer remarkable dimensional stability. BT PCBs offer a range of possibilities and advantages for edge designs such as:

- Lower CTE in XY direction allows for tighter tolerances for assembly. Components can be placed closer to each other without the risk of clashing allowing the integration of more components while maintaining the same footprint.

- Lower CTE in XY direction support the reduction of annular rings by a factor of 1.25 and improves photo and soldermask registration by a factor of 1.5. Thus, enabling advanced PCB capabilities.

- Lower CTE in XY direction reduces the CTE mismatch between PCB and components, thus reducing stress on single components and reducing solder ball failure.

- Lower CTE in Z direction allows for a better control of total thickness, thus allowing a tighter control of thickness tolerance by a factor of 2.

- Lower CTE in XY & Z directions supports to have stronger interconnections for stacked anylayer PCB designs.

Even though low CTE is just one of the advantages of BT PCBs, we can already offer an array of benefits for miniaturization and higher reliability.

Application Spotlight

BT PCBs can be found in several medical applications. For example:

Hearing Aids

BT PCBs enable further miniaturization of hearing aids by enabling highly integrated platforms with multiple components.

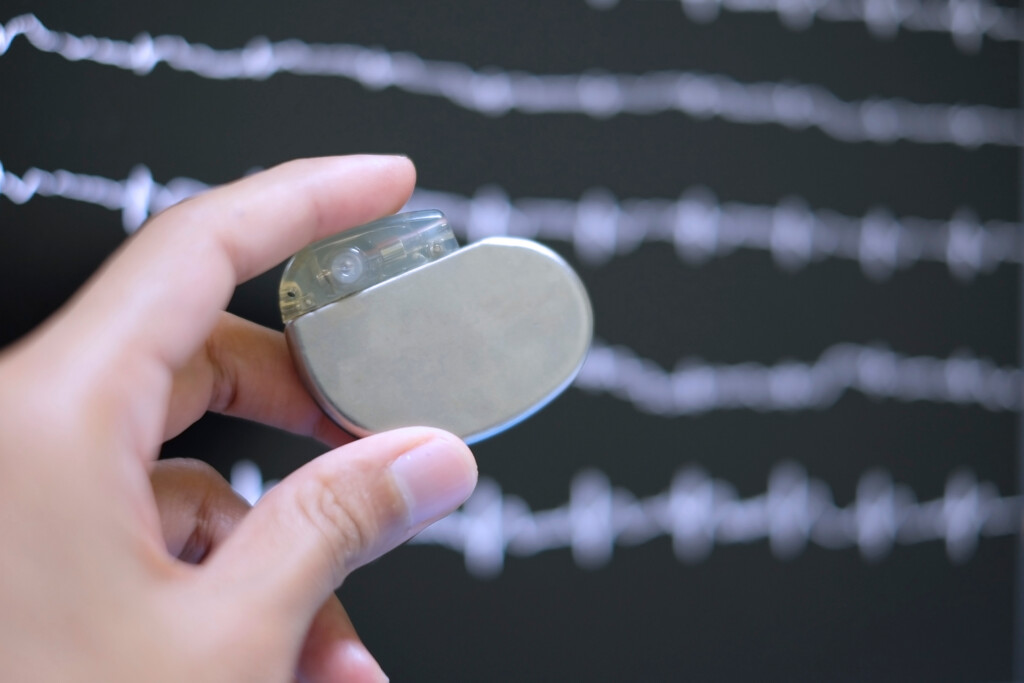

Medical Implants

BT PCBs are used in implantable devices, which require both miniaturization to provide patient comfort and unparalleled reliability to last a lifetime.

Medical Wearables

BT PCBs fulfill the requirements of medical wearables providing a robust and dimensionally stable platform for new developments like continuous measurement of biomarkers.

BT PCBs enable advanced medical devices to become smaller, with added functionalities and high reliability to last a lifetime. Traditional PCB solutions offer limited possibilities to support new and innovative developments, whereas BT PCBs, enable advanced solutions for cutting-edge medical devices.